facilitybossPLS – PrintCapture-Mode

facilitybossPLS PrintCapture-Mode allows you to perform print control and capture of externally pre-printed serial numbers in one step.

In the pharmaceutical industry, it is common practice for folding cartons to be pre-printed by industrial print shops. The service provided by industrial printers is no longer limited to pure layout with static texts. Customer requirements such as serialization, printing of dynamic codes for different markets including helper codes and crypto information are part of the standard range of services offered by industrial print shops.

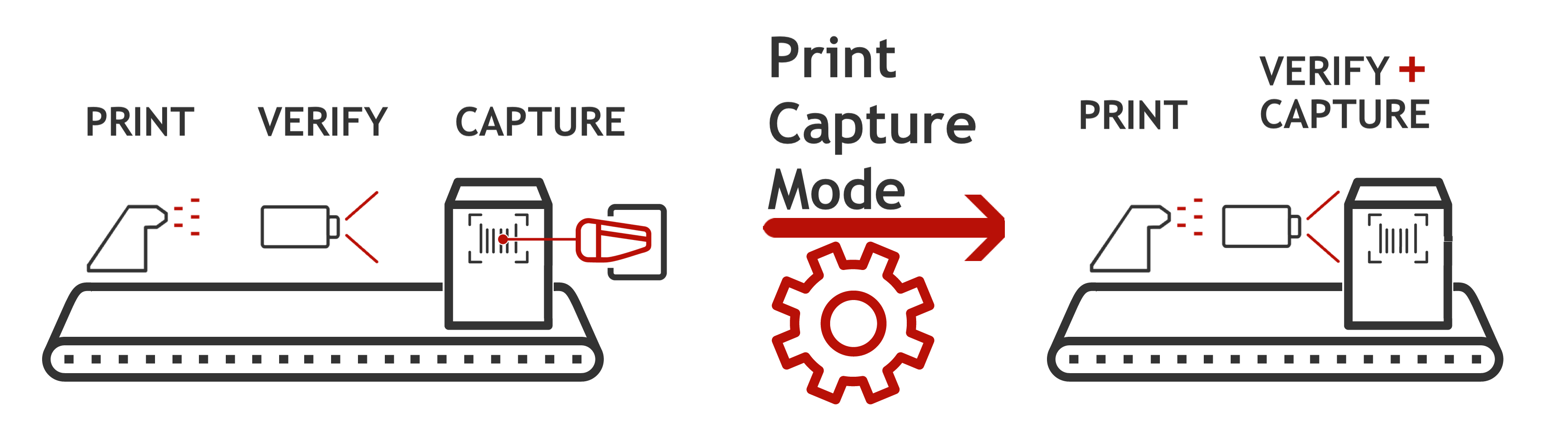

What the industrial printers do not provide, however, is feedback on the serial numbers that have been printed well. This leaves the client in the dark as to which serial numbers were actually printed well and are available for final production. All the client has is the number of folding cartons printed and delivered and a list of all the codes that could have been printed on them. The industrial printers save themselves the effort of recording the good serial numbers because folding boxes can still be destroyed during shipping, packing and the application of further data (batch, expiry, etc.). It is also common for the size of the pre-production to be in the millions, which does not correspond to the final batch size to be produced. Pre-printed folding boxes are assembled and assigned to different batches. Various batch information, e.g. expiry date, can only be printed when the folding boxes are packed and run through production. But which serial numbers are now included in the batch just produced? To answer this question, an additional scanner is usually used to capture the serial numbers of the finished printed and inspected folding boxes and assign them to the batch.

Another scanner means another device to configure, but with deeply integrated cameras, hardware can be easily optimized away with software, and in this case we can replace the scanner with our PrintCapture mode if the pre-printed code and the additional batch-related data printed on it are on the same side and can be recognized with one reading. With the help of our software, the camera not only acts as a control unit in the PrintCapture-Mode, but is configured in such a way that certain information must be present and captured. Thus, two steps are combined and the configuration during setup is simplified, because instead of two devices, only the camera needs to be set up and everything is checked and captured in one step.

For more info visit the related product page here.

https://www.facilityboss.biz/en/products/pls