facilitybossPLS (Production Line System) is facilityboss' core product for your specific production needs. The software's integration of all devices enables the monitoring, control and management of the entire production process directly at the machine.

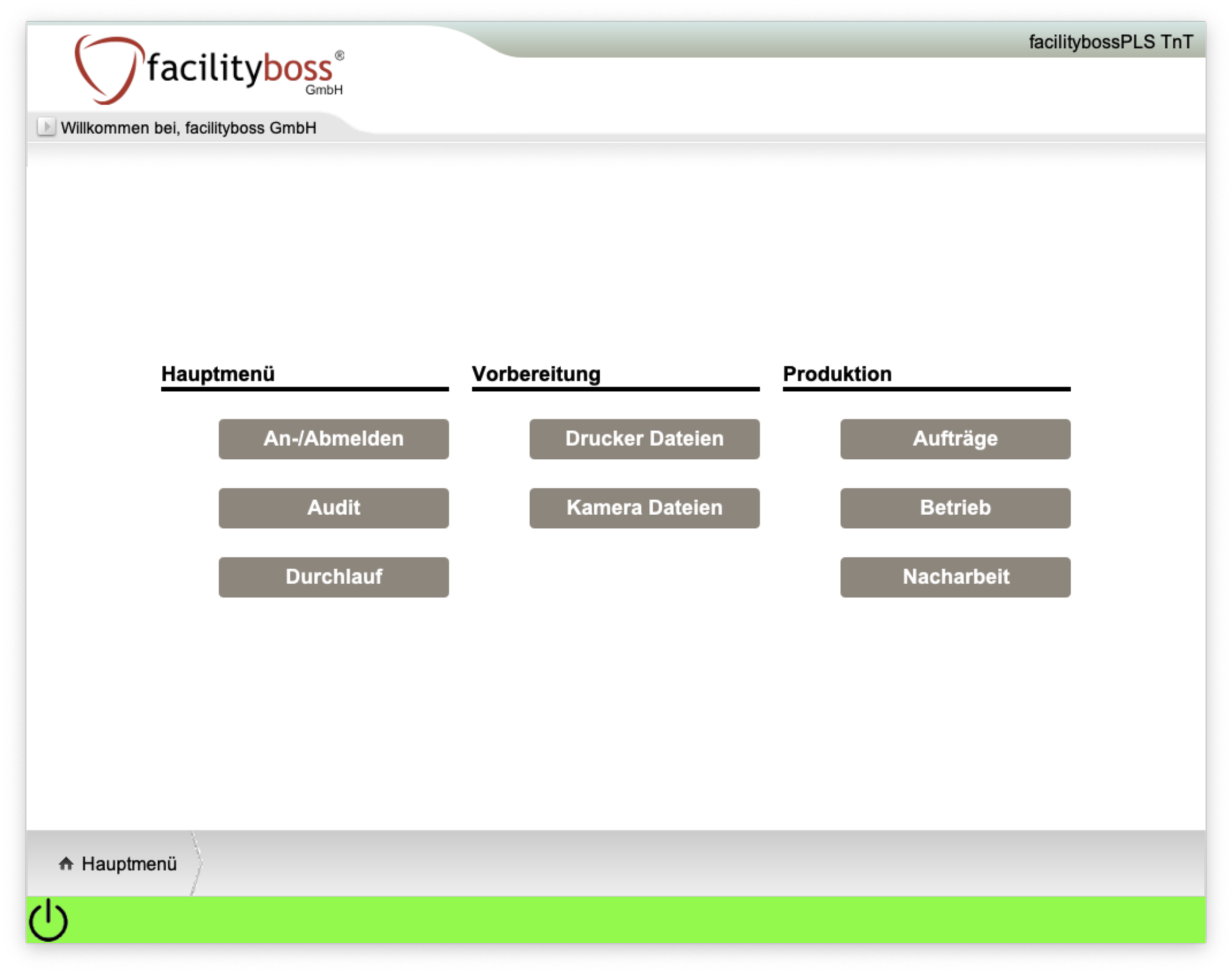

Designed to be straightforward and intuitive, the user interface (HMI) employs a modular approach to efficiently respond to new customer requests or changes to customize the product.

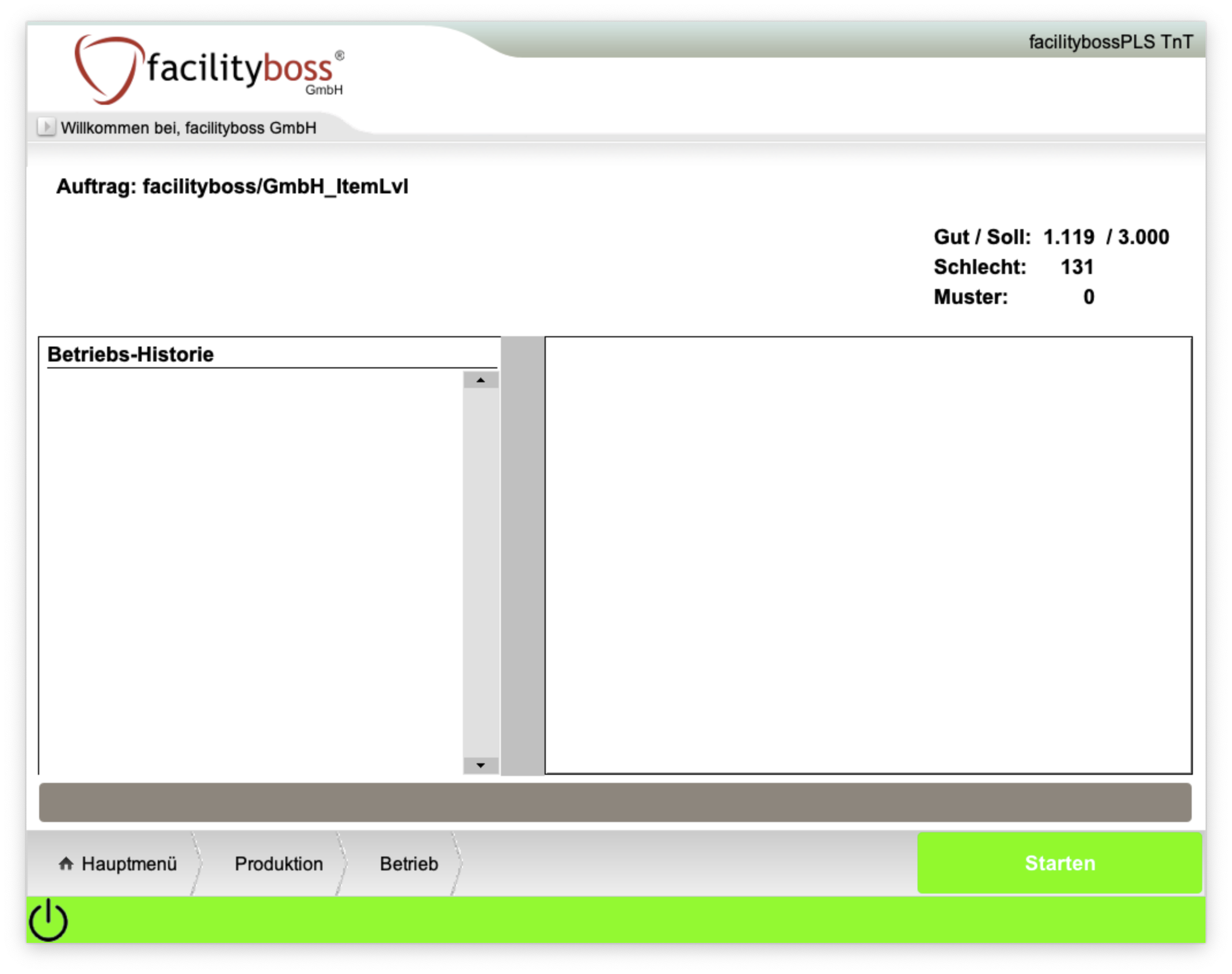

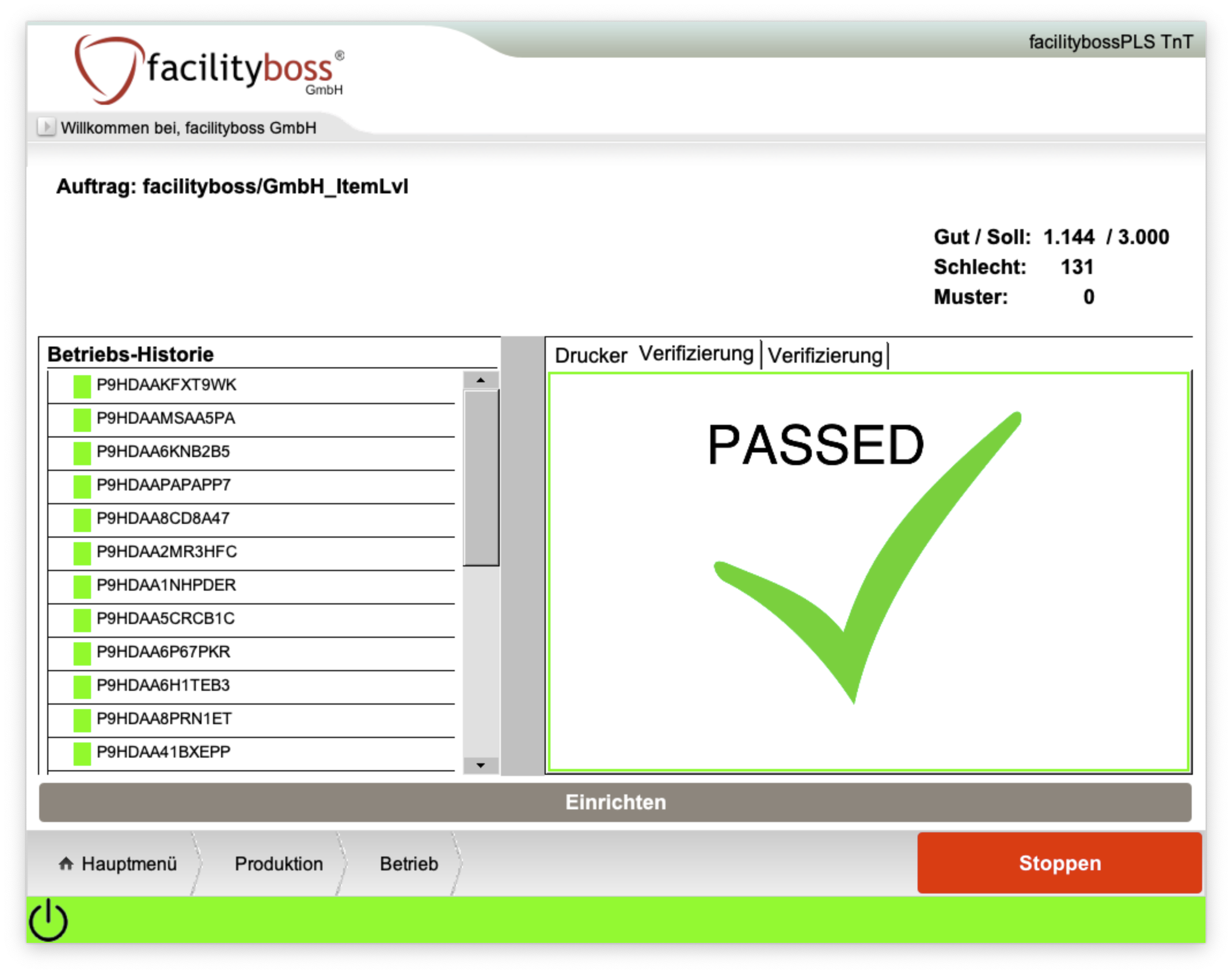

TnT (Track’n’Trace) iis our tailor-made solution for serializing products to prevent counterfeits and ensure traceability. Serialization can be implemented, for example, via GS1 Data Matrix Code (DMC) or also in plain text.

Upon customer request, an alternative serialization coding can be selected to suit your needs, e.g. IFA, Russia, China, or others.

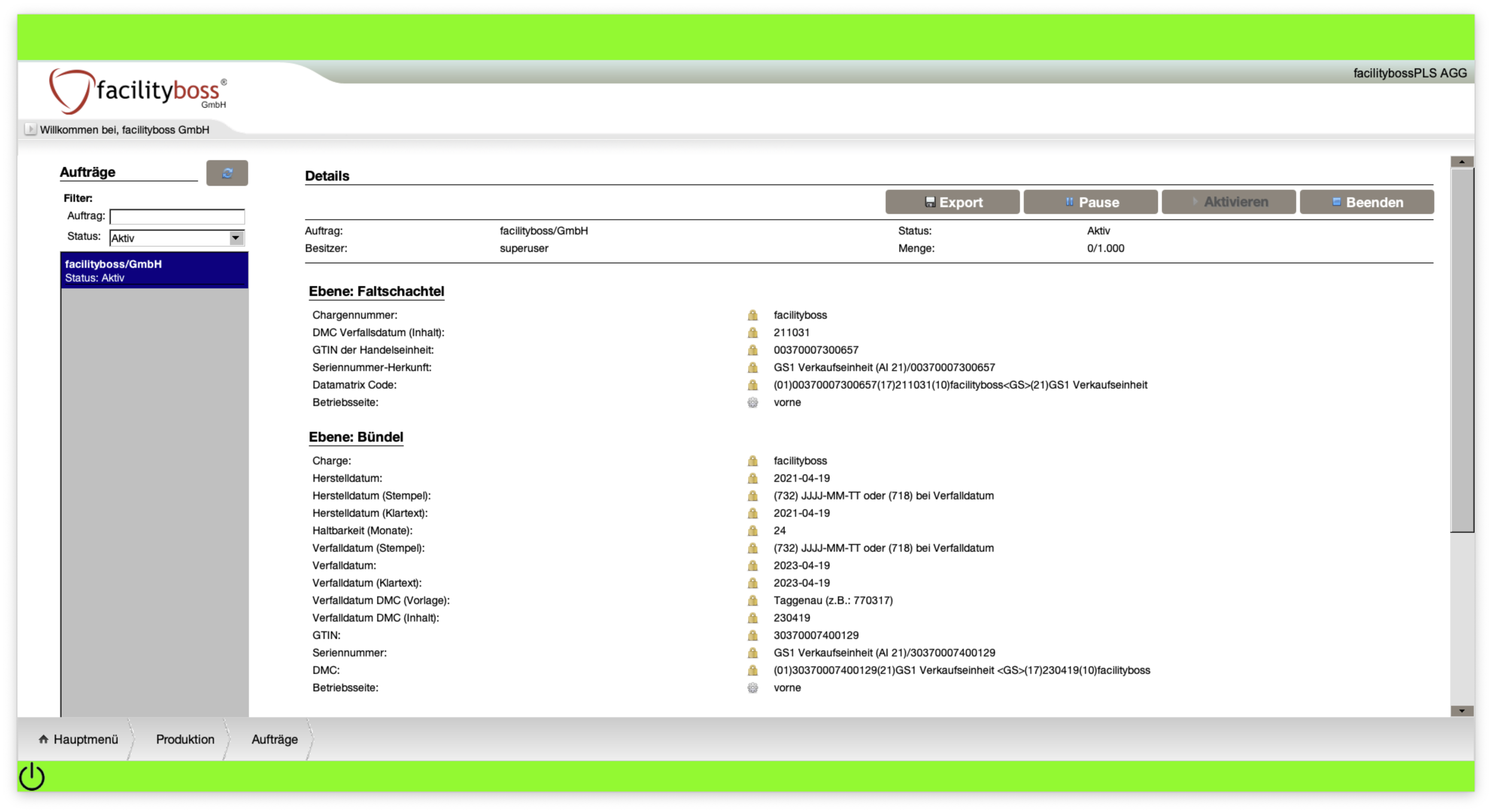

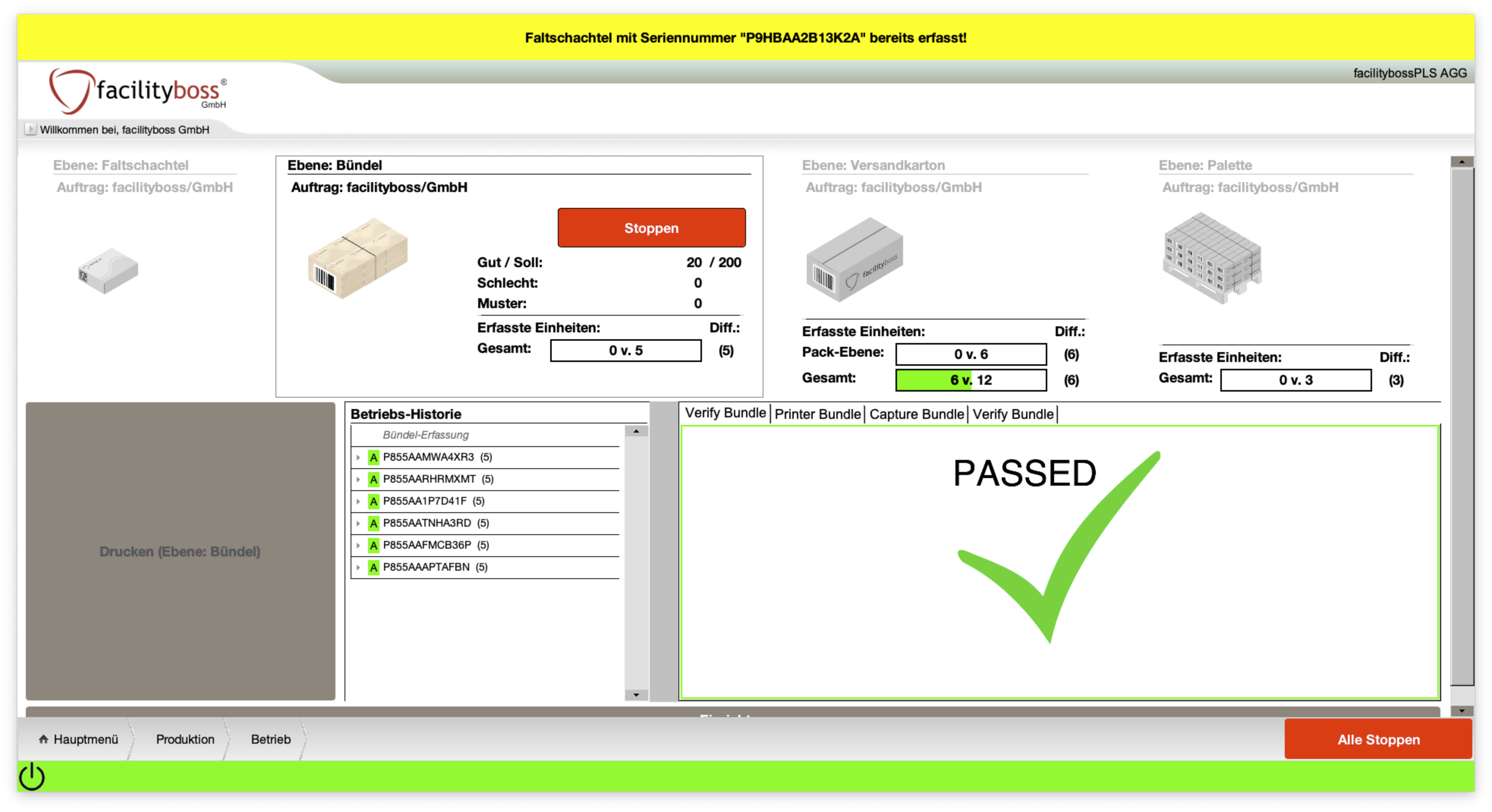

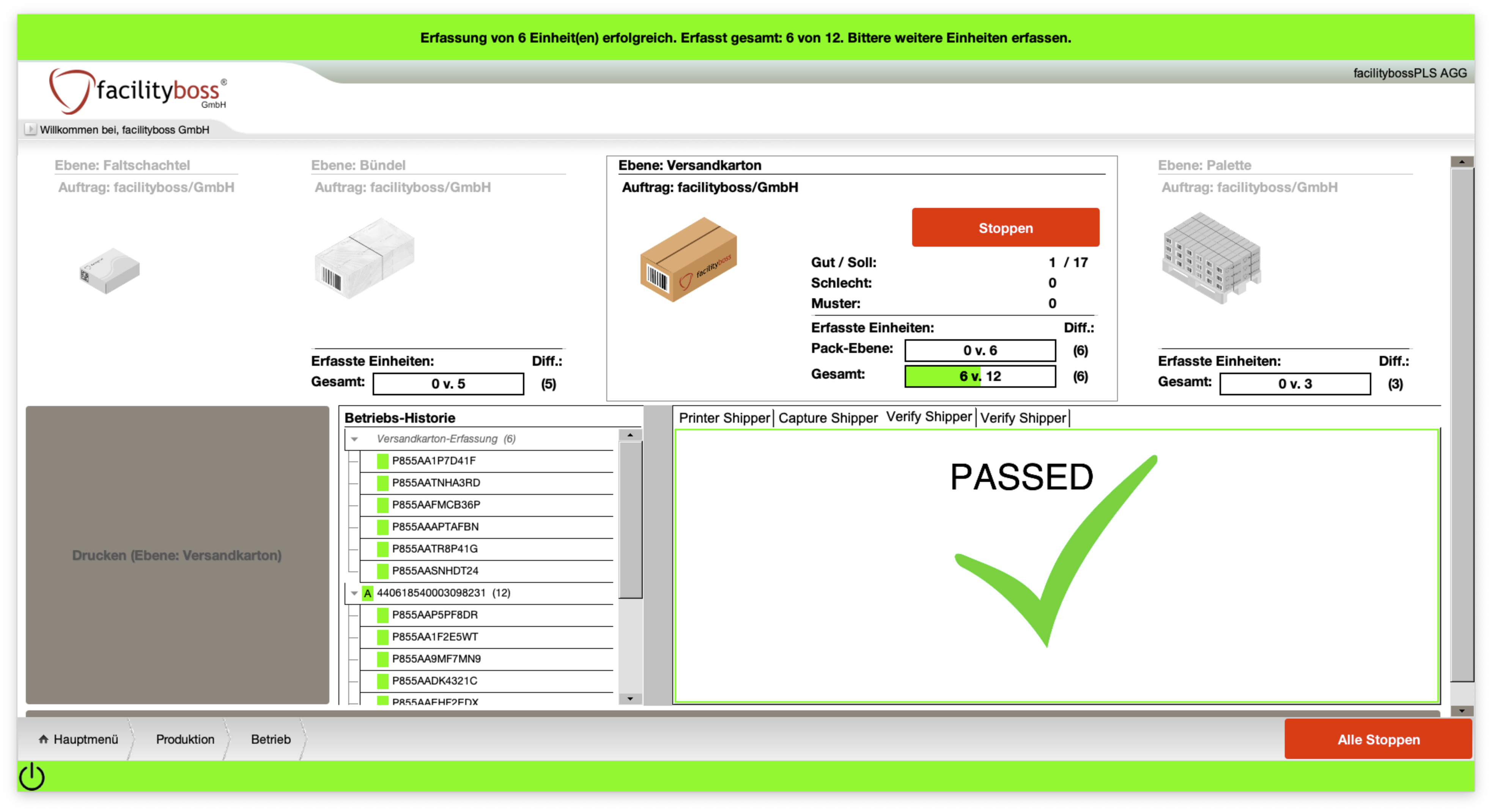

AGG (Aggregation) is our basic product for the aggregation of units. The aggregation marking can be done, for example, via GS1 Data Matrix Code (DMC) or GS1 Bar Code.

The software verifies that the recorded units match the packing scheme and that no duplicates or units are aggregated twice.

Due to the modular design concept used in facilitybossPLS, no marking system is enforced.

Different systems (print, laser, RFID, ...) can be adapted according to your requirements and specification. This also applies to camera systems and scanners, if applicable. Through connections to existing backend systems, such as a Manufacturing Execution System (MES), Enterprise Resource Planning (ERP) or legacy-in-house solutions, facilitybossPLS offers a high degree of flexibility.

Our software can be used as a stand-alone solution, where all required data is entered directly at the machine during production, and/or appropriate modules are installed to import production orders from other (higher level) systems.

Depending on the configuration facilityboss offers you the following possibilities:

- Local management of orders (creation, modification and deletion of orders)

- Audit Trail (21 CFR Part 11)

- Rework (marking products as sample, querying the status of products, marking products as bad)

- Setup (adjusting variable parameters (e.g.: belt speed)

- Number Pool Managment (import numbers and export serialized or aggregated data)

- Managing printer labels and camera scenes

- Monitoring and control of production (e.g.: aggregation queue, live image)