facilitybossMLC (Master Line Controller) is the Level 2 product from facilityboss for the coordination of your line during production. The application is started as a service and distributes the production orders to the corresponding machines of the line.

Production data, such as serial number status or aggregation information, is reported live during production from facilitybossPLS on the machines to facilitybossMLC so that the status of the entire line is consistent and remains so throughout production.

In its central role as an overview of production counters and as a rework station, facilitybossMLC provides the following capabilities without stopping automated serialization on the line.

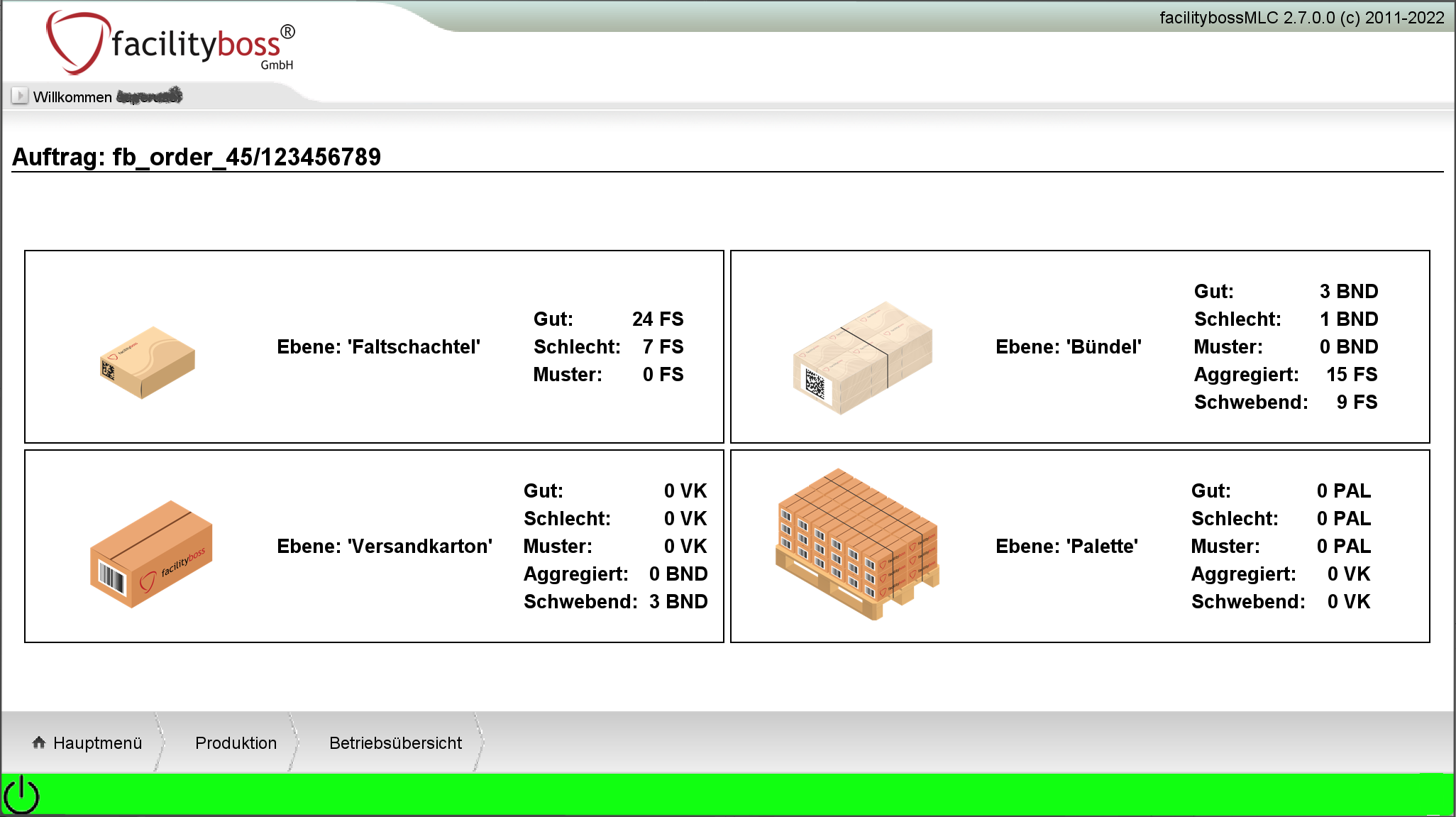

- Real-time counter monitoring of aggregation

- Overview of the condition of the machines

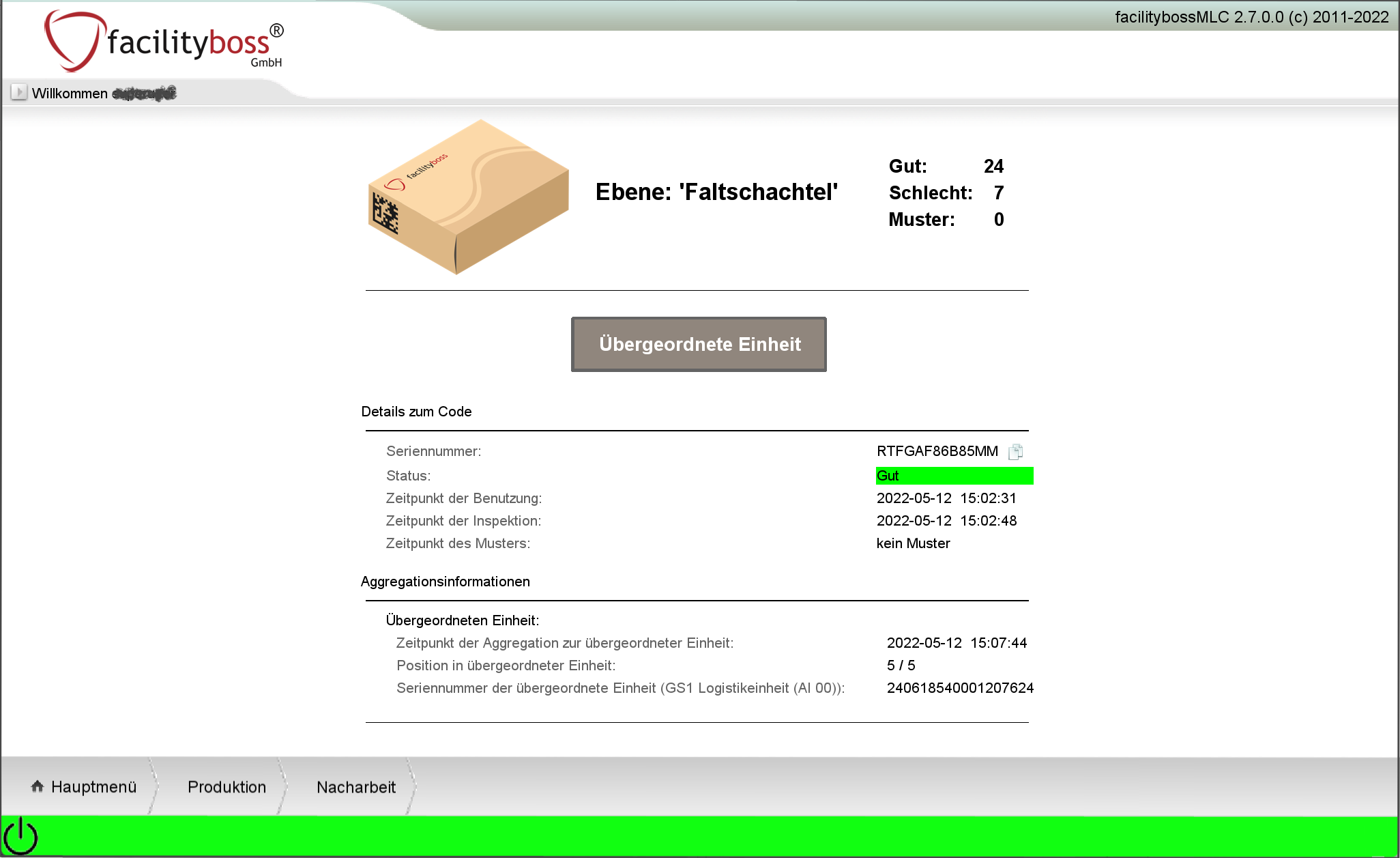

- Query status of units

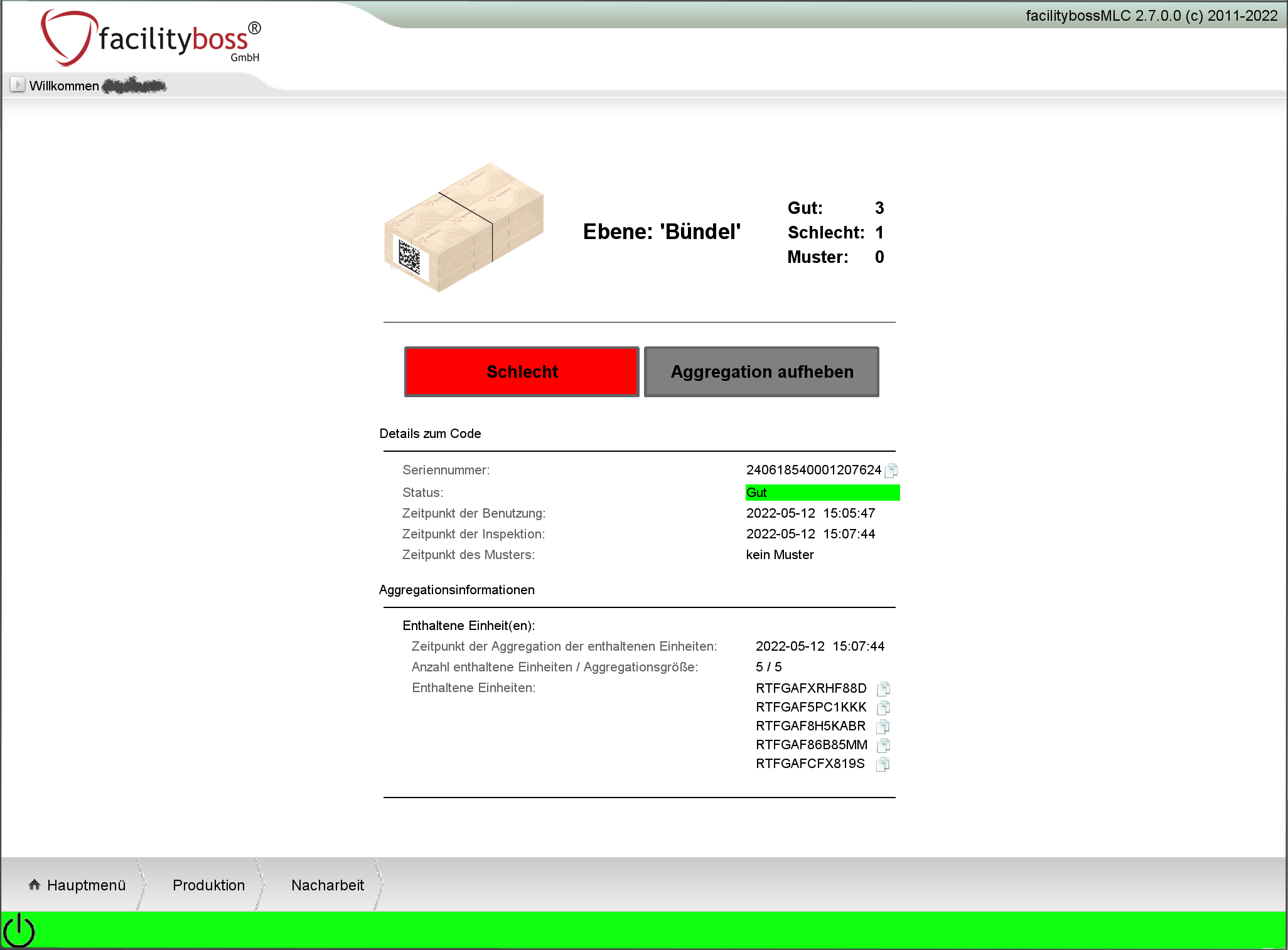

- Deaggregation of damaged units

- Manual rework:

- Marking units as sample

- Marking units as bad

Using a printer, it is possible to use facilitybossMLC in parallel with the fully automated process in the line to manually perform aggregration and serialization-related tasks that.

After production, following tasks are performed:

- Printing of reports

- Rework (see above)

- Coordinated order report to facilitybossLSS (L3) melden