The FK Codingline is the perfect machine for coding and print control of small batches in the pharmaceutical sector. The process-safe friction feeder, the vacuum transport system and the ejection unit are the basis for a reliable process and allow virtually free positioning of the print on print sheets or already glued folding boxes.

In general, the FK Codingline machine and the facilitybossPLS are flexibly adaptable to customer requirements regarding the choice of printer and camera. In projects with Kraus, a combination of a REA JET printer and an OMRON camera has proven successful.

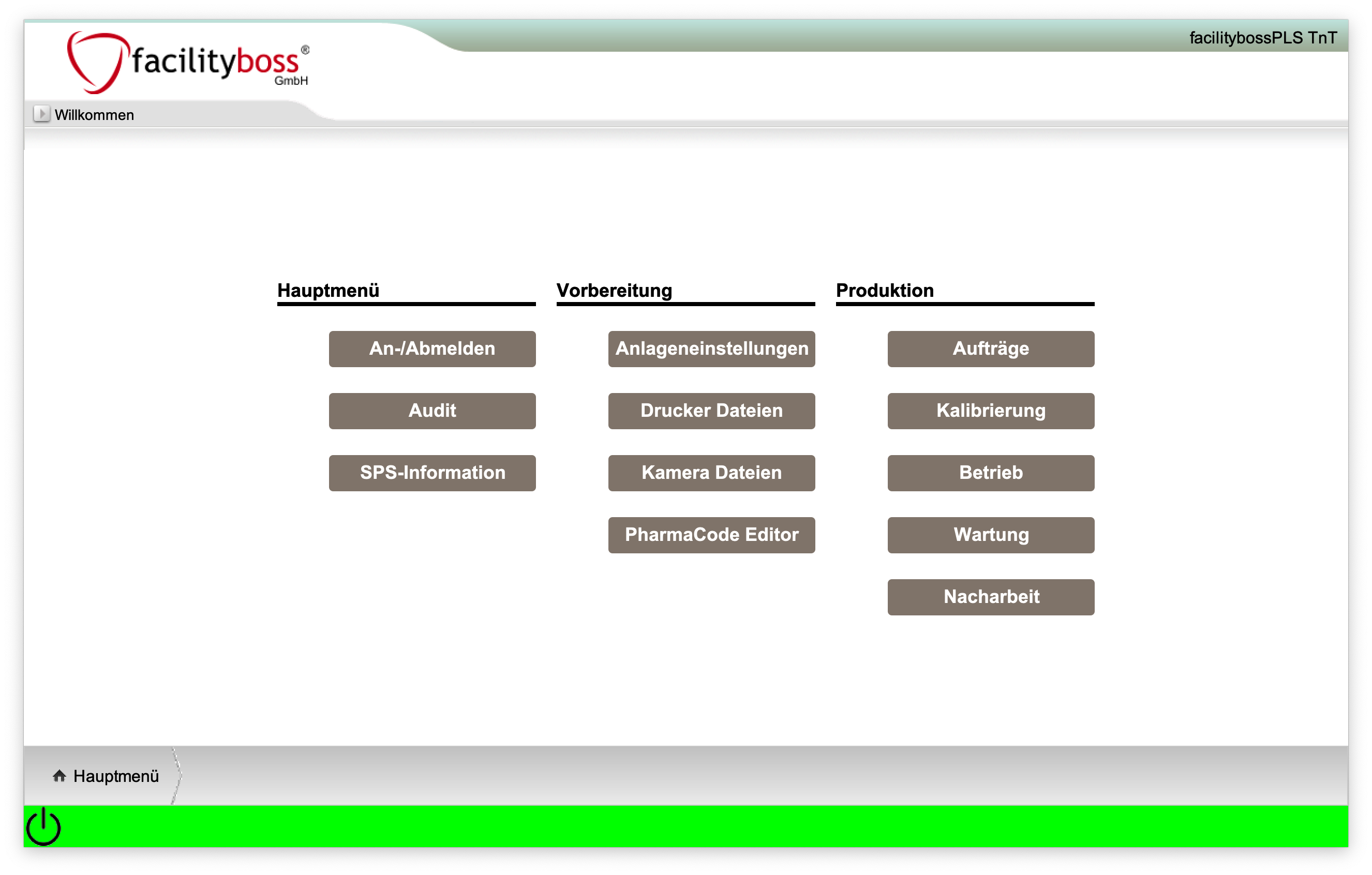

Simple handling and fast adaptability of the machine keep setup times short, even when printing different articles in various formats. This machine concept also reflects the functionality of facilitybossPLS. Article-based storage of machine parameters means that each job does not have to be set individually after initial setting of the article once. If the article number is identical, facilitybossPLS automatically loads the appropriate settings when the job is started.

By fully integrating the machine into facilitybossPLS, all machine settings, such as belt speeds or print offsets, are set directly in the software and the machine's information and messages are also displayed, eliminating the need for a machine display. This saves the operator from having to manually adjust/set the machine settings on an extra display, as the machine settings are managed and set by facilitybossPLS.

Setup

Values such as belt speed, camera and print delays can be adjusted using the software.

Calubration

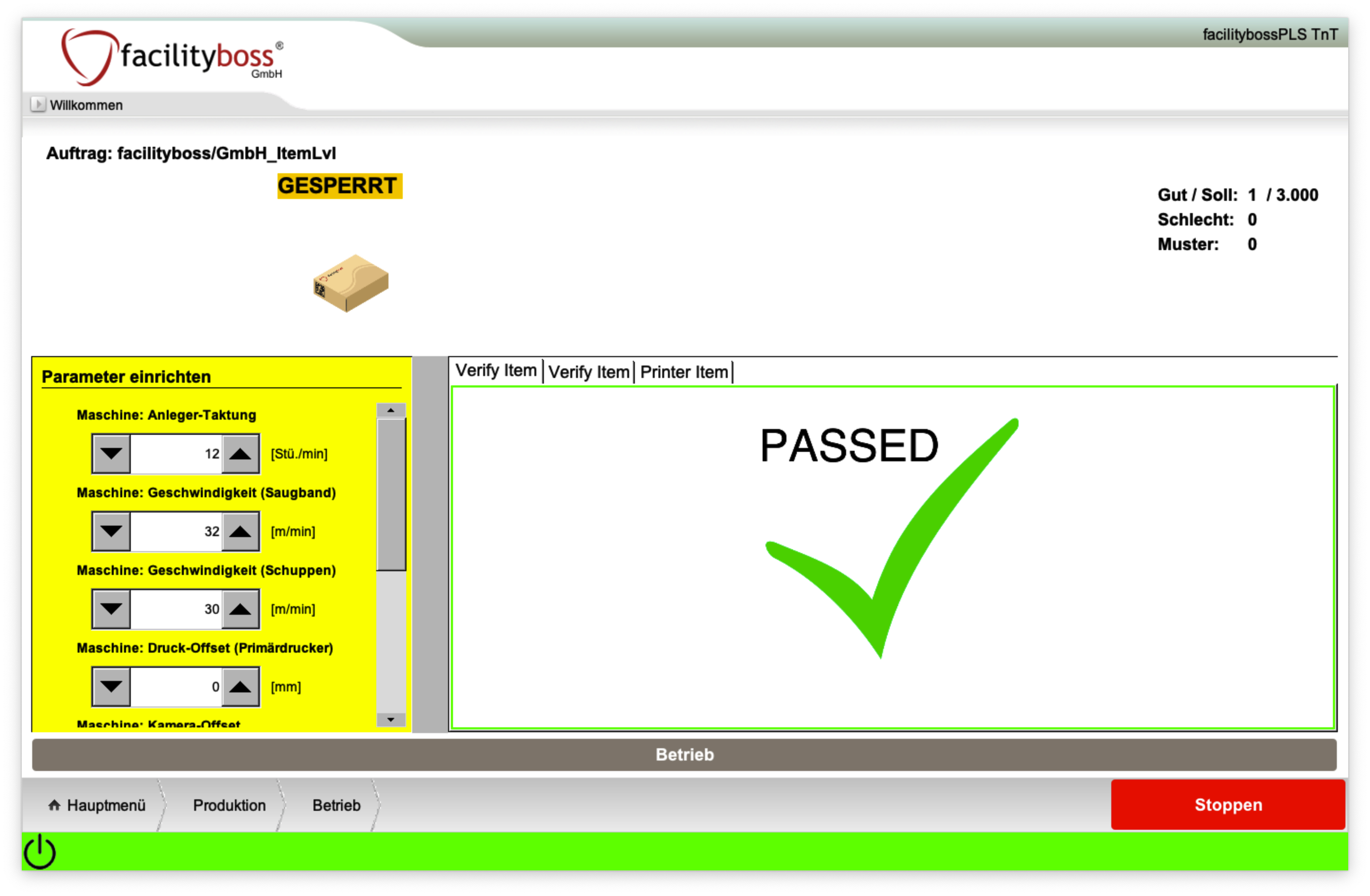

For manual adjustment of rail, print and camera positions, the machine shuts down to 1% of the speed as long as a button is pressed.

Rework

Rework of generated elements allows clearing of elements, de-aggregation and generation of patterns.

Printer

Quantity and manufacturer as per customer's request, in this case, 1 printer with 2 heads.

Camera

Control of texts by means of OCR/OCV and quality check of codes.

Pharmacode

Control of pharmacode with a camera.

Handheld scanner

To scan the codes for rework.